The Importance of Rapid Prototyping Services in Metal Fabrication

The world of manufacturing has evolved significantly over the last few decades, with rapid prototyping emerging as a pivotal aspect of product development. For metal fabricators, understanding the role of rapid prototyping services suppliers is crucial. This article delves into the advantages of rapid prototyping, its processes, and how metal fabricators can benefit from it in creating innovative products.

What is Rapid Prototyping?

Rapid prototyping refers to a group of techniques used to quickly construct a physical part, model, or assembly using three-dimensional computer-aided design (CAD) data. The most common form involves additive manufacturing, but it can also include subtractive processes and other technologies.

Benefits of Rapid Prototyping for Metal Fabricators

Utilizing services from rapid prototyping services suppliers can offer numerous benefits for metal fabricators, including:

- Speed: Products can be developed much faster than traditional manufacturing methods.

- Cost-Effectiveness: Significant cost savings during the development phase due to reduced material waste and less labor required.

- Design Flexibility: Easier to make modifications and optimize designs based on testing and feedback.

- Enhanced Communication: Physical prototypes facilitate better communication among design teams and stakeholders, ensuring everyone is on the same page.

- Market Readiness: Quicker time to market allows businesses to capitalize on opportunities before competitors.

Types of Rapid Prototyping Techniques

Different techniques can be used in rapid prototyping, each with its own unique advantages:

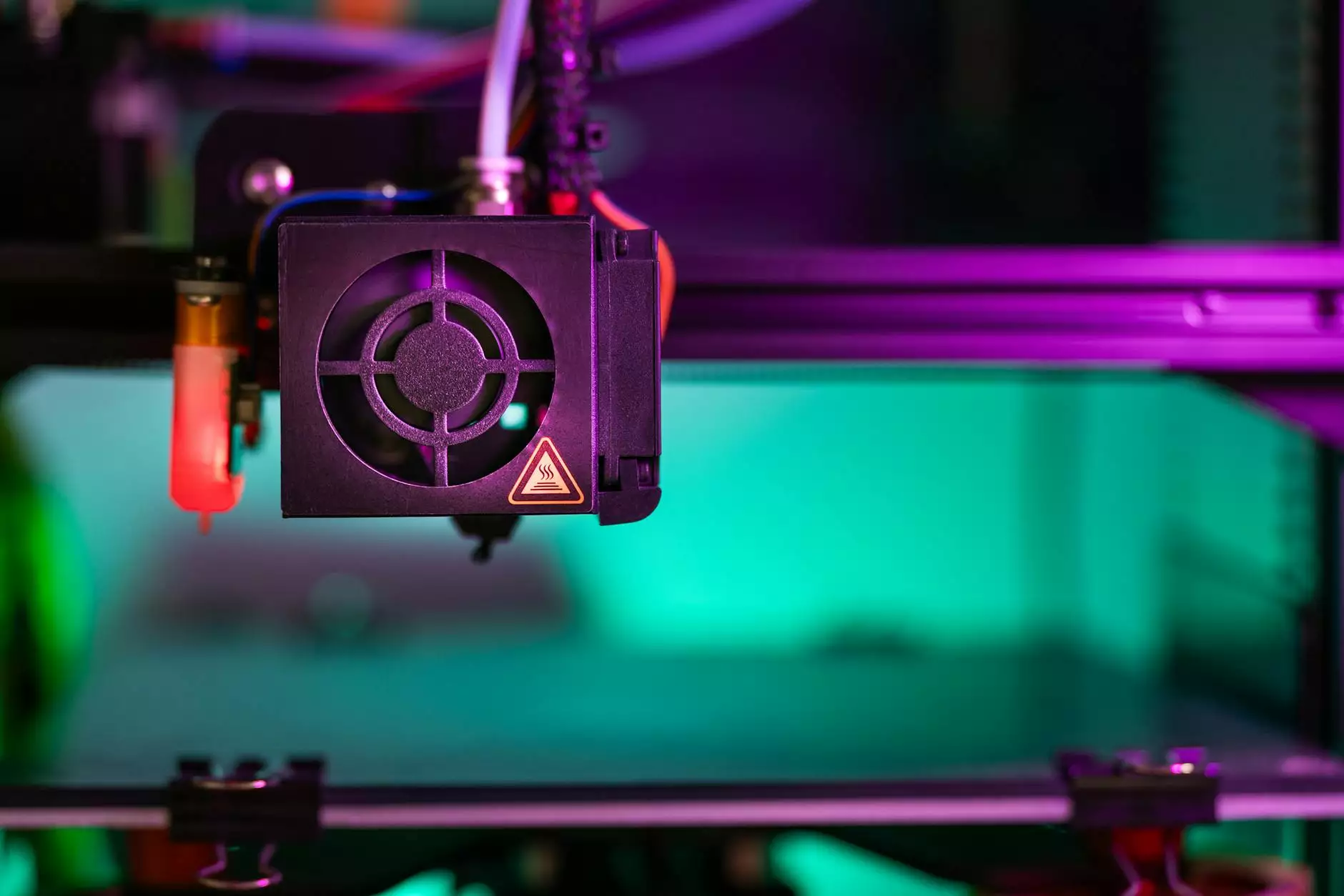

1. 3D Printing (Additive Manufacturing)

3D printing is perhaps the most well-known method of rapid prototyping. It involves layer-by-layer material addition to create a part. This technique allows for complex geometries and is highly customizable.

2. CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is removed from a solid block to create a prototype. This method is excellent for metal parts, where precision and finish are critical.

3. Vacuum Casting

Vacuum casting is often used for producing prototypes in softer materials like polyurethanes. It can be beneficial for creating molds rapidly and testing form and fit before committing to the final manufacturing process.

4. Stereolithography (SLA)

SLA is an additive manufacturing technology that uses a laser to cure resin into hardened plastic. It's renowned for its accuracy and smooth surface finish, making it ideal for visual prototypes.

Choosing the Right Rapid Prototyping Services Supplier

For metal fabricators, selecting the appropriate supplier for rapid prototyping services is crucial. Here are some key factors to consider:

1. Expertise and Experience

Choose a supplier that has a proven track record in metal fabrication and rapid prototyping. Look for case studies or testimonials that demonstrate their capability.

2. Technology Capabilities

Ensure that the supplier offers a range of prototyping technologies to suit your specific project needs, including the ability to handle various materials.

3. Customization Options

A good supplier should provide customization options to meet your specific design requirements. Discuss how they handle unique projects before making a decision.

4. Quality Assurance

Inquire about the quality assurance processes the supplier has in place. Certifications such as ISO can be good indicators of quality standards.

5. Collaboration and Communication

Effective communication and collaboration are essential for successful prototyping. Your supplier should be willing to engage with you throughout the design and development process.

The Process of Rapid Prototyping

Understanding the basic process involved in rapid prototyping can help metal fabricators better engage with suppliers. The typical workflow encompasses the following stages:

1. Design Creation

Initial designs are created using CAD software, detailing specifications and requirements of the prototype.

2. Model Preparation

The CAD model is converted into a format readable by the prototyping machine, with considerations for material and method.

3. Prototyping Phase

The chosen rapid prototyping method is employed to create the prototype. Regular checks can be made to ensure accuracy at this stage.

4. Testing and Evaluation

Once the prototype is created, rigorous testing is performed to evaluate its performance, usability, and design integrity.

5. Iteration and Finalization

Based on feedback and testing, necessary changes are made. This iterative process can significantly improve the final product.

Real-World Applications of Rapid Prototyping in Metal Fabrication

The applications of rapid prototyping in metal fabrication are diverse. Here are a few significant areas where it excels:

- Aerospace Industry: Quick prototyping of components allows for faster design cycles and compliance with rigid safety standards.

- Automotive Sector: Rapid prototyping enables automotive engineers to innovate designs and validate them efficiently.

- Medical Devices: Custom surgical tools and implants can be prototyped for anatomical fit during the product development life cycle.

- Consumer Products: Rapid prototyping allows for quick iterations on product designs, resulting in more market-ready products.

Conclusion

The impact of rapid prototyping services suppliers cannot be overstated in the rapid advancement of metal fabrication. By leveraging these services, metal fabricators can enhance their productivity, innovate effectively, and respond swiftly to market demands. Investing in rapid prototyping can ultimately lead to improved product development cycles and a stronger competitive edge in the ever-evolving manufacturing landscape.

In summary, as the industry's landscape evolves, the collaboration between rapid prototyping services suppliers and metal fabricators will be crucial in driving innovation and meeting the challenges of modern manufacturing. Explore your options today to see how these advanced services can transform your manufacturing processes.