Exploring Industrial Solvent Cleaners: Your Comprehensive Guide

Industrial solvent cleaners play a crucial role in maintaining cleanliness and efficiency in diverse settings, ranging from manufacturing floors to service workshops. As industries become more reliant on sophisticated machinery and equipment, the need for effective cleaning solutions has never been greater. This article delves deep into the world of industrial solvent cleaners, their applications, benefits, and why they are indispensable for commercial enterprises.

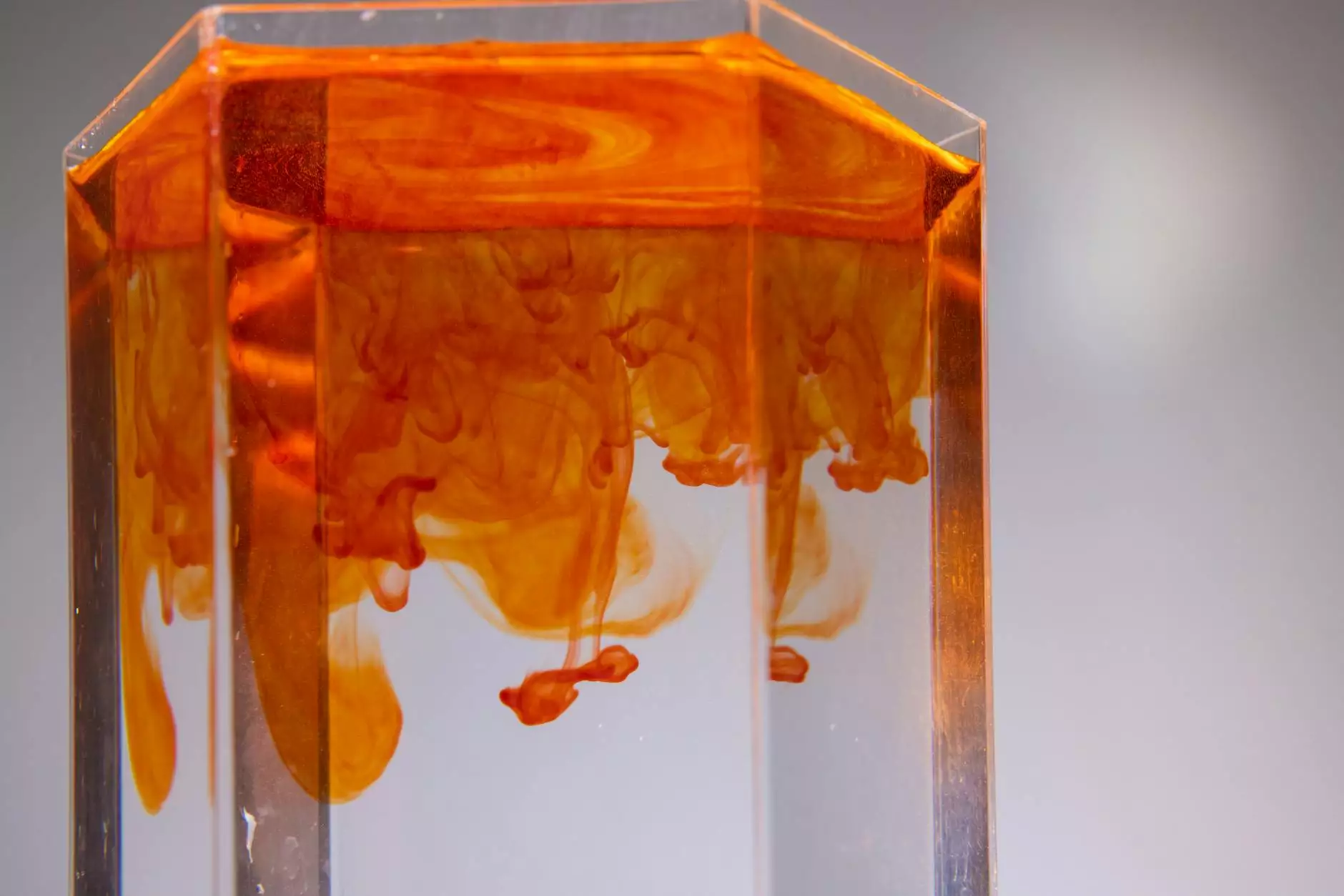

What Are Industrial Solvent Cleaners?

Industrial solvent cleaners are specially formulated chemicals designed to dissolve and remove contaminants, oily residues, greases, and other unwanted substances from various surfaces. These cleaners are integral to processes that demand high levels of cleanliness and precision. They are utilized in various sectors, including:

- Aerospace

- Automotive manufacturing

- Electronics

- Metal fabrication

- Printing and textile industries

The Chemistry Behind Industrial Solvent Cleaners

The effectiveness of industrial solvent cleaners lies in their chemical makeup. Most of these cleaners are composed of solvents capable of breaking down the molecular bonds of contaminants. Common types of solvents used include:

- Aqueous solvents - water-based solutions that are less hazardous and environmentally friendly.

- Hydrocarbon solvents - derived from petroleum, effective for degreasing but can be more toxic.

- Alcohols - ideal for quick evaporation and less residue, making them suitable for sensitive electronics.

- Ketones - widely used for their power to dissolve a wide range of organic compounds.

Benefits of Using Industrial Solvent Cleaners

Utilizing industrial solvent cleaners provides several distinct advantages for businesses, which include:

1. Enhanced Cleaning Efficiency

These cleaners are specifically formulated to tackle stubborn contaminants quickly. This efficiency not only saves time but also reduces labor costs.

2. Versatile Applications

Industrial solvent cleaners are suitable for a wide array of materials, making them ideal for multi-industry use. From metals to plastics and glass, these chemicals can provide superior cleaning properties across various substrates.

3. Environmental Considerations

With the advent of regulations and standards aimed at reducing environmental impact, many modern solvent cleaners are designed to be less harmful. Aqueous and biodegradable options allow businesses to adhere to stricter environmental guidelines without sacrificing effectiveness.

4. Cost-Effectiveness

While the initial investment in high-quality industrial solvent cleaners may seem steep, the long-term benefits of reduced downtime and improved equipment longevity can lead to significant cost savings.

Applications of Industrial Solvent Cleaners

Understanding where and how to utilize industrial solvent cleaners effectively can spell the difference between routine maintenance and a complete operational overhaul.

1. Automotive Industry

In the automotive sector, these cleaners are vital for removing oils and greases before painting or assembly processes. They prepare surfaces, ensuring better adhesion and finish quality.

2. Electronics Manufacturing

Electronics require extreme cleanliness to ensure that no conductive elements interfere with the machinery or the functionality of devices. Solvent cleaners eliminate residues that can impair performance.

3. Aerospace

The aerospace sector requires rigorous cleaning standards due to safety and performance concerns. Solvent cleaners are used to maintain aircraft and components to ensure they operate optimally.

4. Laboratory Applications

In laboratories, maintaining sterile conditions is paramount. Solvent cleaners help in decontaminating surfaces and equipment to maintain integrity and safe operations.

How to Choose the Right Industrial Solvent Cleaner

Selecting the appropriate industrial solvent cleaner can greatly influence the cleaning outcome. Here are some essential tips to help you make an informed choice:

1. Consider the Type of Contaminant

Identify the specific contaminants you are dealing with. Oily substances require strong degreasers, while general-purpose cleaners might suffice for dust and debris.

2. Assess Material Compatibility

Not all solvents are suitable for all materials. Ensure that the cleaner you choose is compatible with the surfaces you need to treat to avoid damage.

3. Evaluate Environmental Impact

If your facility values sustainability, consider products that are biodegradable or less harmful to the environment while still delivering effective results.

4. Check for Regulatory Compliance

Ensure that the cleaners meet local and international safety and health regulations, minimizing liability and promoting worker safety.

Sustainable Solutions in Industrial Cleaning

As industries become more eco-conscious, the demand for sustainable cleaning solutions rises. GBL Cleaning Solution offers a range of products that comply with environmental regulations and are safe for both users and the planet. These solutions are designed to be effective without compromising health and safety.

1. Biodegradable Options

Selecting biodegradable industrial solvent cleaners is an excellent choice for businesses looking to reduce their ecological footprint. These cleaners break down into non-toxic subcomponents once disposed of.

2. Reduced VOC Content

Volatile Organic Compounds (VOCs) are harmful to both health and the environment. Opt for solvent cleaners with low or no VOCs to maintain a healthier workspace.

Best Practices for Using Industrial Solvent Cleaners

To maximize efficiency and safety when using industrial solvent cleaners, consider adopting the following best practices:

1. Proper Training

Ensure that all personnel are adequately trained on the usage of solvent cleaners, focusing on safety protocols and application techniques.

2. Use Personal Protective Equipment (PPE)

Always wear the appropriate PPE, such as gloves and goggles, to protect against potential hazards associated with handling strong chemicals.

3. Follow Manufacturer Guidelines

Adhere strictly to the manufacturer’s instructions for dilution, application, and storage of cleaning solutions to ensure effectiveness and safety.

4. Regularly Review and Update Cleaning Protocols

Conduct periodic reviews of cleaning processes to incorporate new solvent technologies or regulations that may arise.

Conclusion

In the competitive landscape of industry and manufacturing, maintaining cleanliness and equipment efficacy through robust cleaning methods such as industrial solvent cleaners is essential. By choosing the right cleaning solutions, adhering to safe practices, and considering sustainable options, businesses can enhance their operations while contributing positively to environmental standards. Explore the GBL Cleaning Solution range today to find the right products tailored for your industrial needs.