Unlocking the Future of Manufacturing with 3D Printing Prototype Service

In today's fast-paced business environment, the pursuit of innovation is more critical than ever. For manufacturers and creators alike, the ability to transform ideas into tangible products quickly can mean the difference between success and failure. One technology that has significantly altered the landscape of product development is the 3D printing prototype service. This service not only facilitates rapid prototyping but also enhances design flexibility and enables businesses to bring their concepts to life with unprecedented speed and accuracy.

Understanding 3D Printing and Its Role in Prototyping

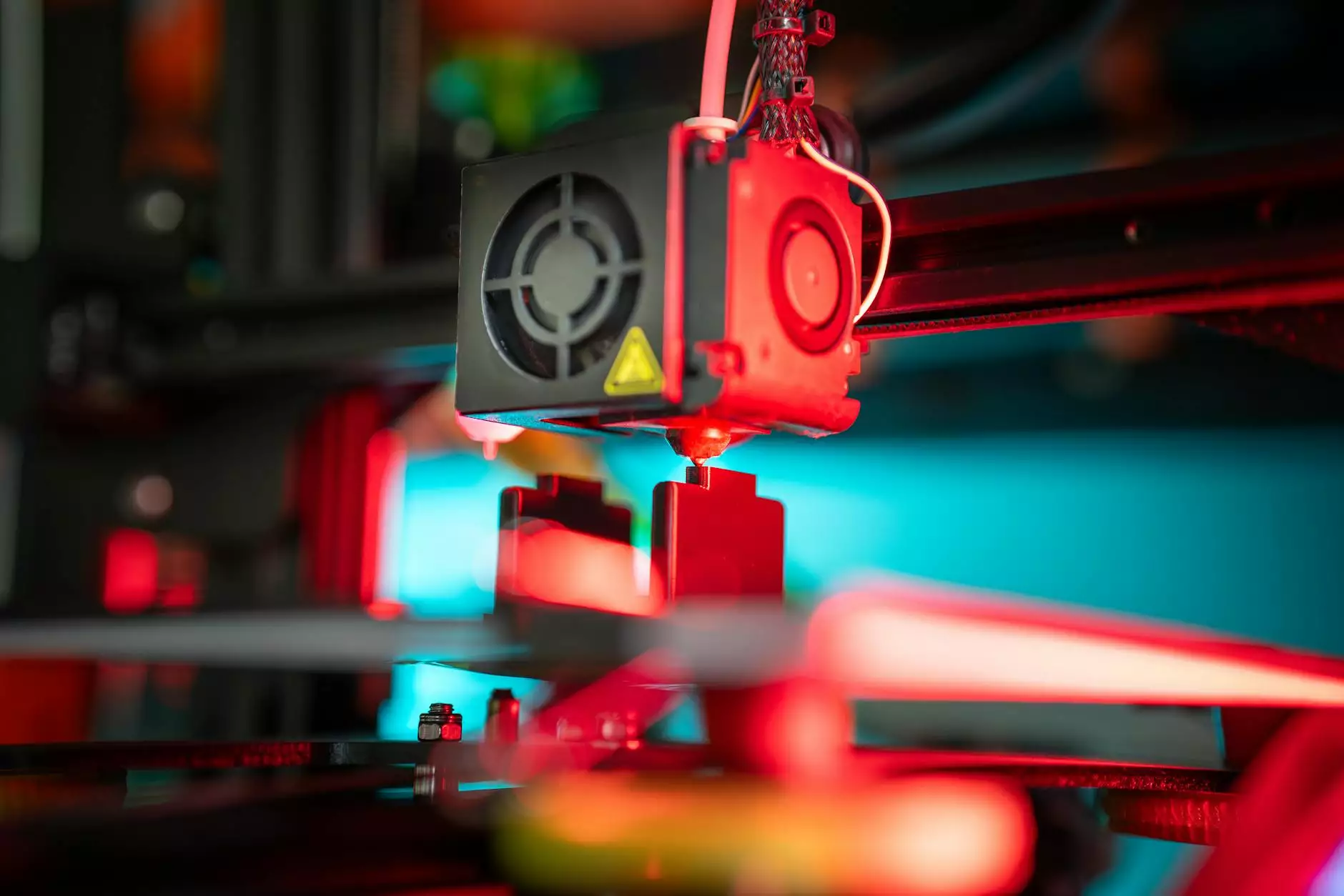

3D printing, also known as additive manufacturing, involves creating three-dimensional objects by laying down successive layers of material. This process allows for intricate designs to be produced with incredible precision. The 3D printing prototype service assists businesses in transforming their digital designs into physical prototypes, streamlining the testing and development stages of product design.

The Process of 3D Printing Prototypes

- Designing the Model: Using CAD (Computer-Aided Design) software, designers create a 3D model of the product they intend to prototype.

- Preparing the File: The model is then converted into a format that the 3D printer can read, typically STL or OBJ.

- 3D Printing: The printer builds the object layer by layer according to the prepared design file.

- Post-Processing: After printing, the prototype may undergo smoothing, painting, or other finishing processes to enhance its appearance and functionality.

Benefits of Utilizing a 3D Printing Prototype Service

From reduced time to market to cost savings, the benefits of leveraging a 3D printing prototype service are extensive. Here are some key advantages:

- Speed: Traditional prototyping methods can take weeks or even months. In contrast, 3D printing can create prototypes in a matter of days, allowing for quicker iterations and faster product launches.

- Cost Efficiency: Reducing the number of materials wasted in the prototyping stage translates to significant savings. Additionally, lesser man-hours contribute to lower overall costs.

- Design Flexibility: Designers can create complex geometries and adjustments on-the-fly without the constraints usually imposed by traditional manufacturing methods.

- Enhanced Collaboration: Rapid prototyping enables teams to visualize ideas and work together more effectively, fostering a culture of innovation.

Applications of 3D Printing Prototype Services Across Industries

The application of 3D printing prototype services spans across numerous industries, enhancing product development in several fields:

1. Aerospace Industry

The aerospace sector relies heavily on rapid prototyping for creating lightweight components that comply with stringent safety regulations. 3D printing allows for the production of complex components at a fraction of the weight traditionally required, leading to significant fuel efficiency and cost savings.

2. Automotive Industry

Automotive manufacturers utilize 3D printing for prototyping parts and accessories, greatly accelerating the design cycle. This process aids in testing new designs for aesthetics, fitting, and performance before mass production.

3. Consumer Products

From electronics to furniture, consumer product designers are leveraging 3D printing to create models that resonate with consumer preferences. Prototyping facilitates market testing and user feedback, helping companies pivot designs based on real-world usage.

4. Medical Devices

In the medical field, 3D printing prototype services enable the rapid creation of customized implants and prosthetics tailored to individual patients' specifications. This personalization leads to enhanced comfort and effectiveness.

Choosing the Right 3D Printing Prototype Service

When selecting a 3D printing prototype service, several criteria should be considered to ensure you partner with a capable provider:

- Experience and Expertise: Look for service providers with a robust track record in your specific industry.

- Technology and Equipment: Ensure that the service uses the latest 3D printing technologies and a variety of materials to accommodate different project needs.

- Customer Support: Choose a provider that offers robust customer support, including assistance during the design phase and after the printing is completed.

- Turnaround Time: Confirm that the service can meet your deadlines without compromising on quality.

Future Trends in 3D Printing Prototype Services

The future of 3D printing prototype services is brimming with potential. As technology advances, we can expect significant improvements in speed, material diversity, and printing accuracy. Some forward-looking trends to watch include:

1. Advancements in Materials

The development of new materials such as bioprinting substances or metal alloys will broaden the applications available to 3D printing, making it feasible for even more industries to adopt these services.

2. Integration with AI

Artificial Intelligence could soon play a pivotal role in optimizing designs, predicting machining errors, and automating the prototyping process to achieve greater efficiency.

3. Increased Customization

As consumer demand for customization grows, 3D printing will become increasingly crucial for producing personalized products tailored to individual needs.

Conclusion: Embrace the Revolution of 3D Printing Prototype Service

The evolution of 3D printing prototype services is redefining how products are designed, developed, and manufactured. By adopting this innovative technology, businesses have the opportunity to enhance productivity, cut costs, and push the boundaries of what is possible. As we move forward, embracing these advancements will be imperative for staying competitive in an ever-evolving market landscape.

At DeepMould, we understand the transformative power of cutting-edge manufacturing solutions. Our expertise in the Metal Fabricators category—coupled with state-of-the-art 3D printing prototype services—positions us as leaders in the industry. Whether you are seeking to optimize an existing design or create a revolutionary new product, we are committed to providing you with the support and technology you need to succeed.